From Concept to Production – Keeping Control In-House

Taking an idea or next generation design to market is a process. Going from concept to production requires many people, much research, futurist thinking, and money. But beyond that, it also takes trust in your manufacturing partners to control the process, information and IP.

Finding the right magnetics partner is no exception when bringing an idea or product to market. Below are the considerations when choosing a magnetics supplier who will be your partner.

Protecting IP

Intellectual Property (IP) should always be protected and guarded. It is important to get to know how much of the design assistance, optimization, production, and testing that will be outsourced by your manufacturing partner. The more operations of the process that remain with one supplier, the less possibility of losing control of the IP.

Our customers have come to rely on us to keep their IP safe. This is why we continue to add more capabilities in-house so that the IP can be better protected and less of the process outsourced. Everyone from our engineering and operations staff, to our production and quality control personnel are in-house, which means it is our combined responsibility to safeguard each of our customers’ information and designs.

Engineering & Design Assistance

Engineers are one of the most valuable resources available to our customers. They provide design assistance, optimization, material and assembly suggestions, production processes, testing set-ups, quality control programs, and knowledge of packaging.

Getting from concept to manufacturing requires engineering expertise in many areas, which is why our staff is comprised of mechanical, materials, electrical, production and quality engineers. Find out if your supplier is able to provide all engineering support, and which engineering assistance would be done by a third-party. For more about our engineering support, click here

If any part of the engineering process is required to be outsourced, plan on providing as little information about the final product to the outsourced partner. This will give third party engineering sources the information they need, but limit them from seeing the whole picture related to the final design.

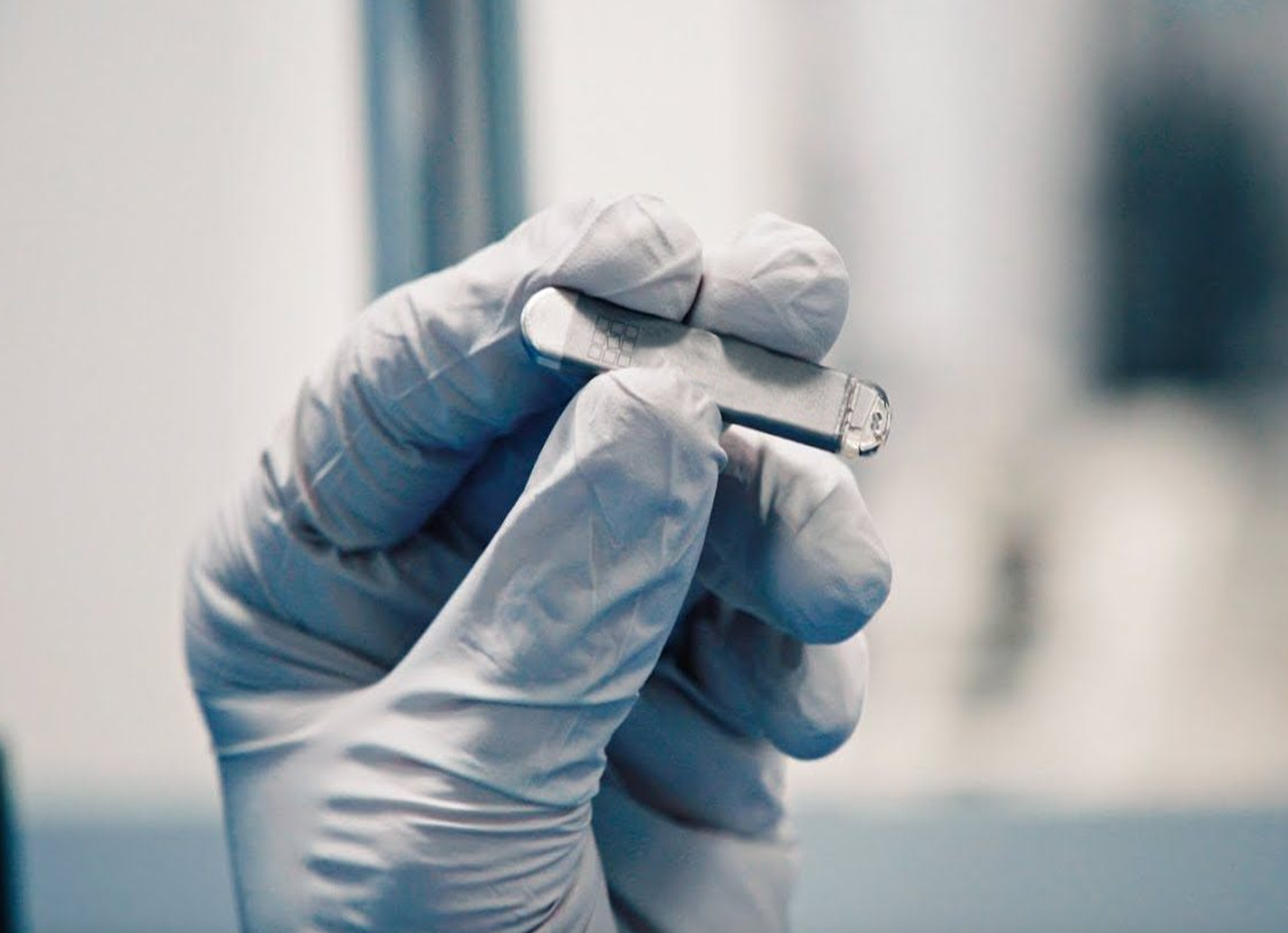

Manufacturing & Assembly

Once a new product, or redesigned product gets past the design, simulation, and optimization phase, it’s time to make prototypes. Whether machined, 3D printed, or built from existing materials, prototypes production is an opportunity for the manufacturing partner to determine set ups and processes as they prepare for mass production. Prototypes are a great practice run for both the customer and supplier, but the key is for both to work together and be transparent about the goals, expectations and final product.

Producing prototypes allows our production team to determine if the manufacturing flow plans, tooling, quality processes, assembly procedures, and staffing requirements need to be adjusted. The planning during the prototype phase allows a manufacturing partner to be prepared as the product enters EVT, DVT, or mass production, and our staff takes this time to be quick and analytical. Because we are able to keep manufacturing of the tooling and product in-house, we are able to produce prototypes quickly and determine if any adjustments can be made to realize efficiencies, cost-savings, or automation.

Click here for an overview of our manufacturing & production capabilities

Quality Control Programs

Every part that is manufactured should have an associated written quality control plan. This allows for repeatability, consistency, and accuracy in every lot, and ensures that all personnel are performing testing according to a documented plan.

Designing a quality control program should not be a “one size fits all” approach. For example, our quality control programs are set up to test for results based upon the end use of the magnet or magnetic assembly. If we manufacture a motor assembly, then we perform the appropriate electrical tests during various assembly stages and as a final check. For a sensor application, we test the gauss reading at the required distance from the sensor. And for a holding application we conduct pull force or shear force tests.

Since we design quality control programs in-house to fit the end use, it also means we keep the appropriate records, maintain the documentation, and continually look for improvements in the process. These results are provided to each customer, and discussions are held to focus on continual improvement and process control.

Change Over for New Parts

In industries that are rapidly introducing new products, a manufacturing partner must be able to change manufacturing or assembly lines quickly. This is especially true in the consumer electronics, robotics, consumer products, security, and motors.

Time to market is critical, and we understand the need to change over systems and manufacturing lines quickly. This means new processes, machining and assembly flow plans, assembly tooling, and quality programs are planned and in place with expediency.

Outsourcing any of the steps during a change-over can lengthen the time of manufacturing, so it is important to understand how a manufacturing partner will get set up and running quickly. If a process has to be completed with a third-party supplier, then it is important for a manufacturing partner to hold the third-party supplier to the same high standards in confidentiality, manufacturing, and quality.

Honesty, Integrity, Experience, Service

A good manufacturing partner makes a quality part. A great manufacturing partner makes the highest quality part, is transparent throughout the stages of development, continually looks at data and analyzes ways to improve, and understands every customer’s goals and objectives.

Our engineering and production staff bring countless in-house capabilities to our customers. We have become vertically integrated so we can control the process and protect our customer’s designs. But, without the mission and goal to get to know each customer and their expectations, we would just be another supplier. We hold high expectations of ourselves to be able to partner with our customer’s so that we can work as a team towards a solution and quality achievement of the same goal.

Summary

Vertically integrated partners can bring a high level of IP protection, manufacturing process control, quality program development, experienced staff, quick response time, and the ability to hold sub-suppliers to same high standards. So, evaluate the capabilities of a manufacturing partner, but also evaluate how each capability is controlled, invested in, and improved.

About SM Magnetics: SM Magnetics is privately owned company, providing assistance with magnets, magnetic circuit design, engineering support, and production. For more information, logon to our website, www.smmagnetics.com , or contact us at 205-621-8841.