Biocompatibility Testing & Validation | Medical Device Magnets - Part 4

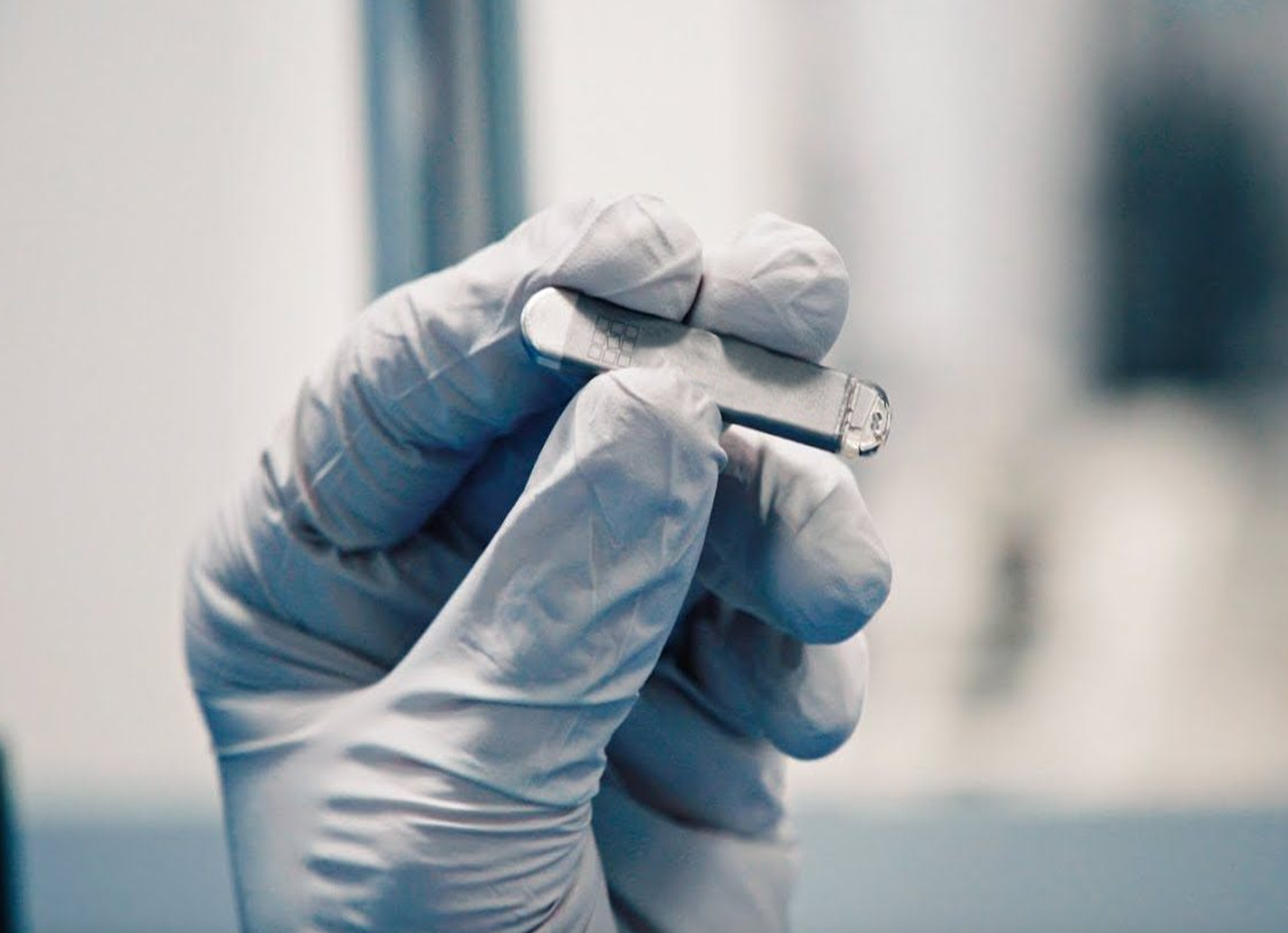

In magnetic engineering for medical devices, it's crucial to understand that biocompatibility testing plays a vital role. This applies to a diverse range of medical devices, with examples ranging from implantable devices like artificial joints and pacemakers to non-implantable equipment such as catheters, surgical instruments, and diagnostic tools. The specific testing requirements depend on the intended function of the device and the duration of its contact with the human body. In our experience implantable devices usually require more comprehensive testing protocols due to their prolonged interaction with bodily tissues. This consideration is especially pertinent when incorporating magnetic components into these devices, as magnetic properties can influence biocompatibility and safety. Biocompatibility testing presents itself in a variety of forms, which encompass:

- Cytotoxicity Testing: This testing assesses the potential of the magnet or materials containing the magnet to cause harm to living cells. It is often one of the first tests conducted to determine if the magnet poses any cell toxicity.

- Irritation and Sensitization Testing: These tests evaluate the potential for local skin or tissue irritation and allergic reactions when the magnet is in contact with the body.

- Implantation Testing: If the permanent magnet is used in an implantable device, such as a pacemaker, long-term implantation testing may be required to assess the effects of the magnet on tissues and organs over an extended period.

- Biological Risk Assessment: This involves an overall evaluation of the device's biocompatibility, considering all available information from testing, material composition, and clinical data.

It's important to note that the specific testing requirements may vary depending on factors such as the device's classification, intended use, and the materials used. Some magnetic testing we can perform on our magnets to ensure high quality and consistency includes the following:

- Salt Spray 24-48 hours

- Dimensional Measurement

- Plating/Metallographic

- Accelerated Life

- Magnetic Moment

Be sure to speak with one of our magnet experts to learn more about our testing and to ensure the appropriate tests are performed based on your requirements.

Figure 1: Salt Spray Test Machine Figure 2: Metallographic testing for plating thickness

In the realm of magnetic engineering for medical devices, the importance of rigorous testing and validation cannot be overstated. Biocompatibility testing is a top priority of ours, ensuring our medical grade magnets and assemblies meet the stringent safety standards demanded by the healthcare industry. At SM Magnetics, we understand the paramount significance of these tests in guaranteeing the safety and efficacy of our products. Our commitment extends beyond mere compliance, as we undertake additional magnetic testing to uphold the highest standards of quality and consistency. From salt spray analysis to dimensional specifications, our meticulous approach ensures that every magnet and assembly meets the rigorous demands of medical device manufacturing. By adhering to stringent testing and validation processes, we not only uphold the trust of our partners, but also contribute to the advancement of medical innovation. Together, we continue to forge a path toward safer, more effective medical solutions, guided by the principles of excellence and integrity.

About SM Magnetics: SM Magnetics is a privately owned company, providing design assistance, magnetic circuit design, engineering support, and production for permanent magnets and magnetic assemblies. For more information contact our technical staff or visit our website www.smmagnetics.com.