Design Considerations for Permanent Magnet Selection in Medical Devices - Part 2

At SM Magnetics we understand the complexities of bringing a product to market and have worked with many companies through the process to develop unique medical magnets and magnets for medical devices. Our experience with magnetic design and complete assemblies in applications that enter the body, or assist outside of the body, make us a knowledgeable partner to the medical innovators. This means working closely with our customers to provide magnets and assemblies that meet medical requirements.

Permanent Magnet Selection and Integration in Medical Devices

Factors to Consider when Choosing Magnets

Selecting the appropriate permanent magnet for medical devices involves careful consideration of several factors to ensure optimal performance, safety, and compatibility. Here are some key factors to consider:

-

Magnetic Strength: The magnetic strength of the magnet is crucial for devices like MRI machines, magnetic sensors, and magnetic separators. The required magnetic field strength depends on the specific application and the intended use of the device.

-

Corrosion Resistance & Biocompatibility: As we discussed earlier, biocompatibility is essential for any material used in medical devices. The chosen magnet material should not cause adverse reactions or harm to the human body when it encounters tissues or bodily fluids. Magnets with good corrosion resistance, such as neodymium magnets coated with protective layers, are suitable for these applications.

- Temperature Stability: Some medical procedures involve sterilization processes that use very high temperatures. Magnets should maintain their magnetic properties within the required temperature range without demagnetizing or losing strength. For more information on the materials and their intended operating temperatures, see our

-

Size and Shape: The size and shape of the magnet must align with the device's design and intended use. Depending on the application, magnets can be customized to fit into specific spaces and provide the required magnetic field distribution. In medical innovation today being able to manufacture micro sized magnets, that are lighter in weight, is very important as the devices are getting smaller and smaller.

- Magnetic Field Distribution: For medical imaging devices like MRI machines, the uniformity and strength of the magnetic field are crucial for accurate imaging. Magnets with consistent field distribution are preferred.

- Magnetization Direction: The direction of magnetization affects how the magnet interacts with its surroundings. Choosing the right magnetization direction is essential to achieve the desired magnetic field orientation and strength.

-

Regulatory Compliance: Medical devices need to meet regulatory standards and guidelines. Ensure that the chosen magnet materials and designs comply with relevant regulations. It is essential to meet biocompatibility with magnet coatings.

-

Long-Term Stability: The magnet's performance should be stable over time. It should not experience significant degradation or loss of magnetization with repeated use or over the device's expected lifespan.

The selection process involves balancing these factors to meet the specific needs of the medical device while ensuring patient safety and regulatory compliance. It's often helpful to collaborate with magnet manufacturers, materials experts, and engineers with experience in medical device design to make informed decisions.

Ensuring Secure Attachment and Integration

In medical magnet applications, achieving secure attachment and seamless integration is paramount for device reliability and patient safety. Meticulous engineering, medical grade adhesives, and precision mounting techniques are essential to guarantee the magnets stay in place and function as intended. Below are some key magnet integration techniques:

- Adhesive Bonding: Using medical-grade adhesives specifically formulated for healthcare applications is crucial when bonding magnets to materials such as plastics, metals, or ceramics in medical assemblies. These adhesives ensure secure attachment, maintaining the device's functionality and safety under various conditions. In medical devices like dental prosthetics, for example, adhesive bonding is used to affix magnets, which must remain securely in place despite exposure to bodily fluids, varying temperatures, and other stresses. The durability of adhesive is vital to prevent device failure and ensure patient safety.

- Mechanical Fastening: Mechanical fastening methods, such as screws or bolts, are employed to secure magnets in place. This is particularly useful in applications where magnets need to be removable or replaced, such as in prosthetic limbs where magnets assist in attachment and detachment.

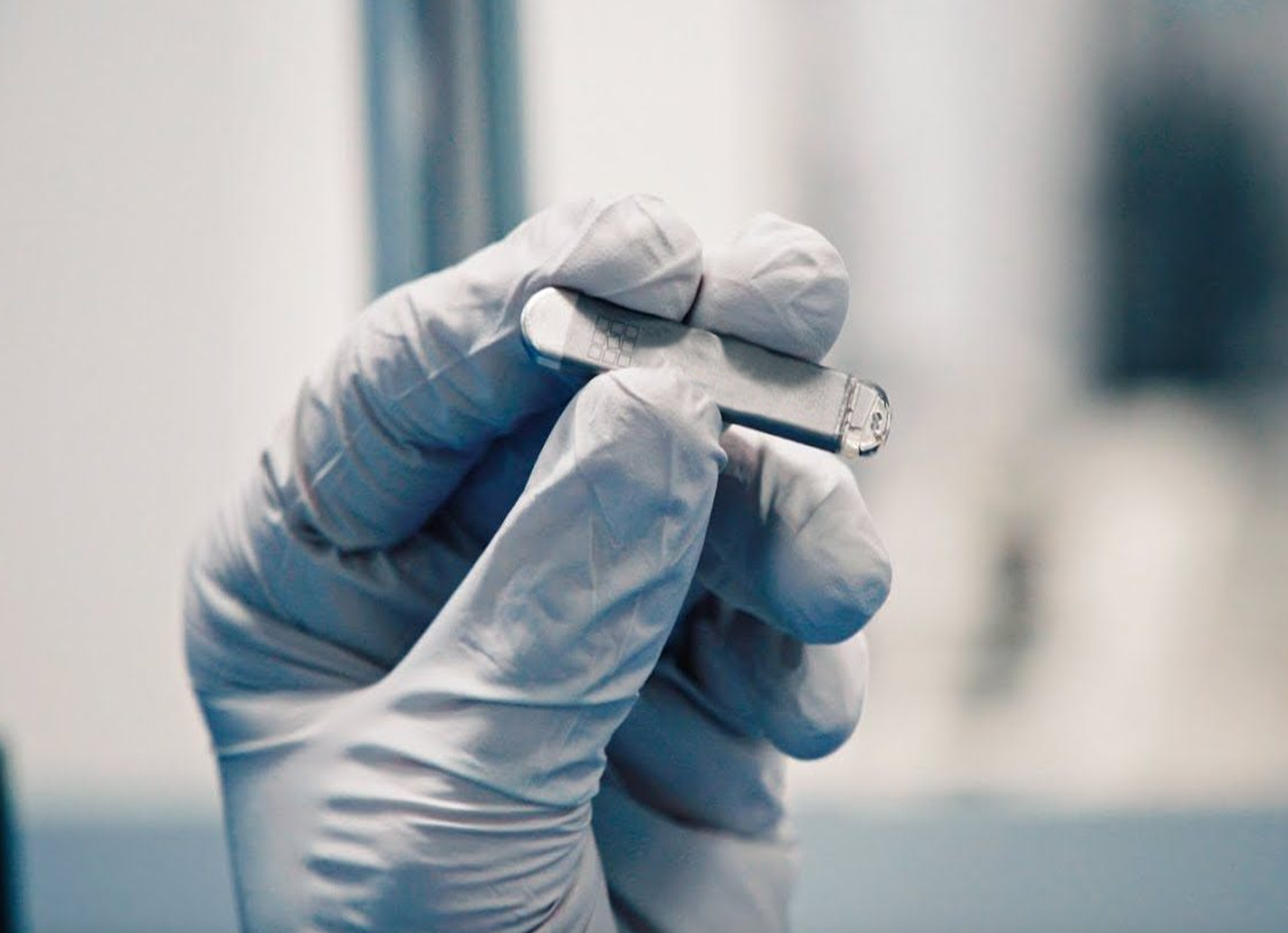

- Magnetic Assemblies: Micro magnets are often incorporated into assemblies to provide secure attachment and integration within medical devices. In applications like catheters and cochlear implants, precise placement and secure alignment of these magnets are essential to ensure proper functionality. Integration strategies play a key role in maintaining the stability and performance of the device, ensuring that the magnets remain firmly in place throughout its operation.

- Custom Housings or Embedded Magnets: Precision mounting techniques for magnets in medical devices can involve either creating custom housings or embedding the magnets directly within the device structure. Custom magnet housings ensure secure attachment while protecting the magnet from environmental factors such as bodily fluids and tissues, as commonly required in medical implants. Alternatively, embedding magnets directly into the device's structure offers a low-profile, integrated solution. This method is used in applications like medical pill cameras, where small magnets are embedded to assist with navigation through the digestive tract. Both techniques offer secure and reliable solutions tailored to the specific needs of medical devices.

When integrating magnets into medical devices, it's crucial to carefully consider the application's unique requirements, such as biocompatibility, size constraints, and environmental factors. Each technique should be chosen based on the specific needs of the device to ensure both secure attachment and effective integration, contributing to the overall success of the medical application. Contact one of technical experts to start the conversation about your specific application.

About SM Magnetics: SM Magnetics is a privately owned company, providing design assistance with magnets, magnetic circuit design, engineering support, and production. For more information contact our technical staff or visit our website www.smmagnetics.com.