Magnet Coatings Guide: How to Select the Right Surface Protection for Your Application

Selecting a magnet coating is not simply a corrosion decision.

It is a design variable that directly affects durability, performance, assembly tolerances, and long-term reliability.

Whether you're designing for automotive systems, medical devices, pump & fluid handling, robotics, or consumer electronics, coating selection should be evaluated alongside magnet grade, geometry, and operating environment.

This guide outlines key coating types, performance characteristics, and when each is appropriate

Engineering Considerations Before Selecting a Magnet Coating

Before selecting a coating, evaluate:

1. Operating Environment

- Ambient indoor exposure

- High humidity or condensation

- Salt spray or marine conditions

- Chemical exposure

- Full fluid immersion

2. Temperature Profile

- Maximum sustained temperature

- Intermittent peak exposure

- Thermal cycling frequency

3. Assembly & Tolerance Sensitivity

- Air gap sensitivity

- Press-fit applications

- Adhesive bonding requirements

- Stack-up tolerance impact

4. Mechanical Stress

- Impact risk

- Abrasion

- Handling during assembly

5. Regulatory Requirements

- Biocompatibility

- Food-grade compliance

Many coating failures originate from environmental assumptions made early in design.

In sealed pump assemblies and fluid handling environments, coating degradation can compromise containment integrity and significantly reduce system lifespan.

Common Magnet Coatings & Their Characteristics

Below is a technical overview of widely used coating options, including performance characteristics and recommended use cases.

Nickel (Ni-Cu-Ni)

Nickel is the most common standard magnet coating.

- Triple-layer plating: Nickel–Copper–Nickel

- Corrosion resistance in ambient indoor environments

- Light protection against minor chipping

Thickness: 15–25 µm

Max Working Temperature: ~200°C

Cost: Low

Recommended For:

- Indoor, controlled environments

- Motors, sensors, generators

- Automotive and pump systems without aggressive exposure

Avoid When:

- Prolonged humidity exposure

- Salt spray or marine environments

- Chemical immersion

Nickel is sufficient for controlled conditions but should not be relied upon for aggressive environments.

Black Nickel

Black nickel uses the same Ni-Cu-Ni structure with a darkened surface finish.

- Primarily aesthetic variation

- Similar corrosion resistance to standard nickel

Thickness: 12–25 µm

Max Working Temperature: ~200°C

Cost: Low

Recommended For:

- Applications requiring darker appearance

- Controlled indoor environments

Avoid When:

- Humid, marine, or chemical exposure

Epoxy Coating

Epoxy is a polymer-based barrier coating designed to improve corrosion resistance.

- Strong resistance to salt air and saltwater

- Good adhesion when using magnet-rated adhesives

- Surface can scratch if mishandled

Thickness: 15–30 µm

Max Working Temperature: ~200°C

Cost: Medium

Recommended For:

- Marine or outdoor environments

- Automotive exposure

- Applications requiring higher corrosion resistance than nickel

Avoid When:

- Ultra-tight tolerance assemblies

- Abrasion-heavy environments without controlled handling

Epoxy is often selected when corrosion resistance requirements exceed nickel capability.

Parylene

Parylene is a conformal vapor-deposited coating known for uniformity and thin application.

- Extremely thin and consistent

- Suitable for biocompatible applications

- Strong chemical resistance

- May require undercoating in prolonged saltwater exposure

Thickness: 1–70 µm

Max Working Temperature: ~120–305°C

Cost: Batch dependent

Recommended For:

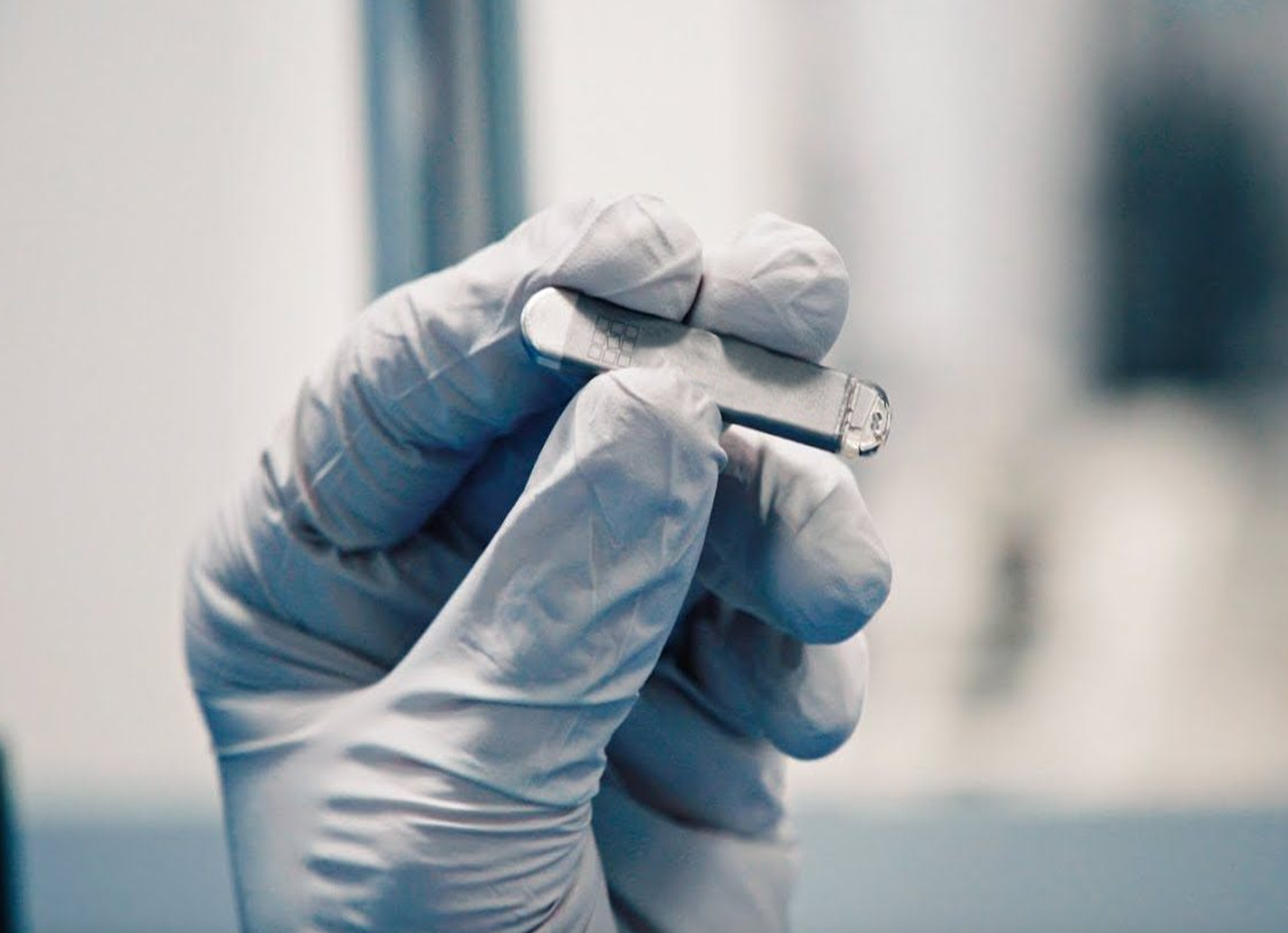

- Medical and implantable devices

- Tight tolerance assemblies

- Precision robotics and sensor systems

Avoid When:

- Heavy mechanical abrasion

- Long-term saltwater exposure without undercoating

Parylene is frequently chosen when coating thickness control and uniformity are critical.

Zinc

Zinc is a thin metallic coating primarily used for basic corrosion protection.

- Moderate resistance in ambient air

- Limited protection in humid or fluid environments

Thickness: 4–10 µm

Max Working Temperature: ~120°C

Cost: Low

Recommended For:

- Cost-sensitive indoor applications

- Low-temperature environments

Avoid When:

- High humidity

- Fluid or chemical exposure

Gold

Gold is typically applied over a Ni-Cu-Ni base layer and is often selected for medical applications.

- Biocompatible surface option

- Thin layer provides limited salt spray resistance

Gold Thickness: 0.1–1 µm

Max Working Temperature: ~200°C

Cost: High

Recommended For:

- Medical devices (in-body and external use)

- Specialty electronic interfaces

Avoid When:

- Aggressive salt spray environments

- Cost-sensitive industrial applications

Titanium Nitride (TiN)

Titanium Nitride is a hard, wear-resistant coating with strong chemical resistance.

- Strong adhesion to substrate

- High durability

- Suitable for medical use

Thickness: 3–6 µm

Max Working Temperature: ~500°C

Cost: Medium

Recommended For:

- Medical components

- High-wear mechanical interfaces

- High-temperature systems

Avoid When:

- Low-cost commodity applications

Injection Molded Plastic

Injection molding encapsulates the magnet within a protective polymer housing.

- Excellent impact resistance

- Strong corrosion protection

- Requires molds and tooling

- Significantly increases overall thickness

Thickness: 1–2 mm

Temperature Limit: Dependent on selected polymer

Recommended For:

- Impact-prone environments

- Wash-down or fluid exposure

- Applications requiring mechanical durability

Avoid When:

- Tight air gap sensitivity

- Space-constrained assemblies

Molded PTFE (Teflon)

Molded PTFE provides excellent chemical and fluid resistance.

- Suitable for autoclave environments

- Poor adhesive bonding — mechanical retention recommended

Thickness: 1.5–3 mm

Max Working Temperature: ~250°C

Recommended For:

- Medical applications

- Food processing environments

- Chemical immersion

Avoid When:

- Adhesive bonding is required

- Tight tolerance assemblies

Spray PTFE

Spray PTFE is a thinner alternative to molded PTFE.

- Food-grade option

- Suitable for smaller geometries

- Good corrosion resistance

- Surface can scratch if mishandled

Thickness: Typically, 20–25 µm

Max Working Temperature: ~250°C

Recommended For:

- Food-grade applications

- Moderate fluid exposure

- Smaller components

Avoid When:

- High abrasion environments

Rubber Coating

Rubber coating adds impact protection and surface friction.

- Provides mechanical durability

- Improves grip in holding applications

- Requires tooling

- Increases overall thickness

Thickness: ~0.5 mm

Max Working Temperature: ~135°C

Recommended For:

- Holding or mounting applications

- Industrial environments requiring friction

Avoid When:

- High-temperature systems

- Precision assemblies

Rhodium

Rhodium is a dense, wear-resistant coating offering strong resistance to corrosion and surface degradation.

- Enhanced surface durability

- Excellent corrosion resistance

- Strong wear performance

- Suitable for medical applications

Thickness: 1–5 µm

Max Working Temperature: ~200°C

Melting Point: ~2,000°C

Cost: High

Recommended For:

- Medical devices

- Specialty automotive components

- High-performance assemblies requiring surface integrity

Avoid When:

- Cost-sensitive applications

- Environments where nickel or epoxy is sufficient

Rhodium is selected when surface durability and corrosion resistance are critical performance requirements.

Decorative Coatings (Copper, Chrome, Silver)

These coatings are primarily aesthetic finishes with limited corrosion protection.

Recommended For:

- Cosmetic applications

- Consumer products

- Jewelry

Avoid When:

- Marine environments

- Chemical exposure

- Industrial or medical reliability requirements

How Coating Thickness Affects Magnetic Performance

Coating thickness increases effective air gap.

In applications sensitive to flux density — such as motors, sensors, or magnetic couplings — even small dimensional increases can:

- Reduce field strength

- Affect torque output

- Influence sensor calibration

- Impact press-fit tolerances

Coating selection should be evaluated in conjunction with magnetic performance requirements.

Prototyping & Off-the-Shelf Coated Magnets

During early-stage validation, many standard plated and coated magnets are available for rapid evaluation through our eCommerce division, SuperMagnetMan.

This allows engineering teams to test geometry, air gap sensitivity, and environmental performance before finalizing production specifications.

For applications requiring specialized coating thickness, undercoating strategies, or regulatory validation, custom engineering support may be required.

Engineering Support & Custom Solutions

For applications involving:

- Aggressive chemical exposure

- Sterilization cycles

- Tight air gap sensitivity

- High-temperature operation

- Regulatory compliance

Early coating evaluation can prevent downstream redesign.

SM Magnetics provides engineering guidance for material selection, coating trade-offs, environmental validation, and production transition to support long-term reliability.

This strengthens lifecycle authority.

About SM Magnetics: SM Magnetics is a privately owned company, providing assistance with magnets, magnetic circuit design, engineering support, and production.To learn more about our capabilities or to discuss your next project, contact us via email or call our experts at 205-621-8841.