Optimizing Pump Performance with Magnetic Drive Solutions

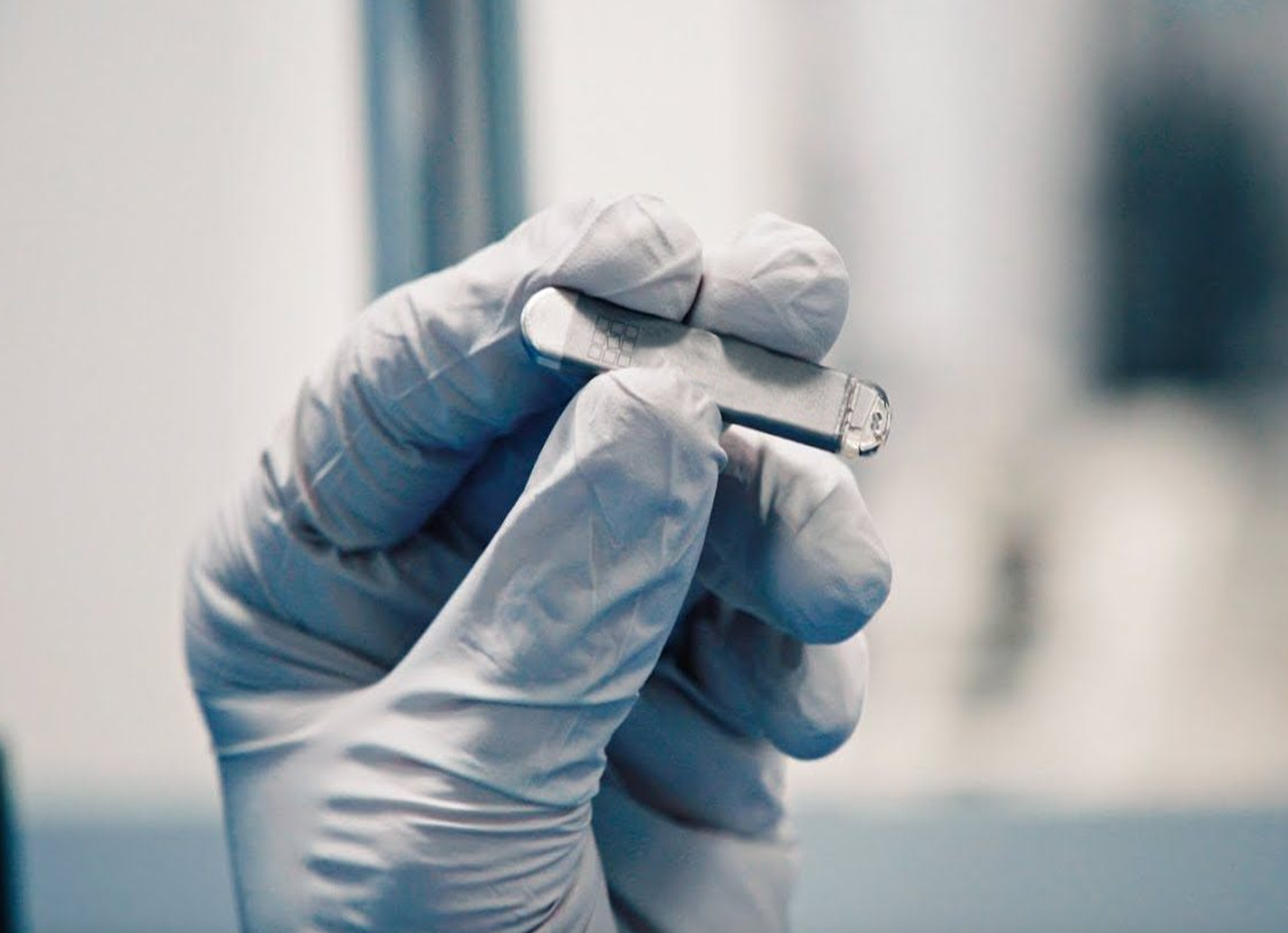

At SM Magnetics, we specialize in designing and manufacturing high precision custom magnets and magnetic assemblies tailored to meet the unique needs of your applications. Our commitment to quality and innovation ensures that our solutions perform reliably across diverse industries.

In the dynamic realms of pump and fluid handling applications, reliability, efficiency, and safety are non-negotiables. Equipment failures or inefficiencies can lead to costly downtime, compromised product quality, and safety hazards. As leaders in magnet technology, SM Magnetics recognizes the pivotal role that magnetic solutions play in addressing the unique challenges faced by companies operating in these sectors. In this blog, we'll explore how harnessing magnet expertise can significantly enhance reliability, efficiency, and safety in pump and fluid handling applications.

Enhanced Reliability with Magnetic Drive Technologies:

Traditional pump seals can be prone to wear, leakage, and maintenance issues. Magnetic drive technologies offer a compelling alternative by eliminating the need for dynamic seals, resulting in leak-free and maintenance-free operation. By employing magnetic coupling and magnetic drive technologies, pumps and fluid handling equipment can achieve enhanced reliability and uptime, even in corrosive fluid environments and high-temperature settings.

While magnetic coupling and magnetic drive technology can achieve enhanced reliability there are steps to take during manufacturing to ensure that your pumps will meet these standards. Selecting the right magnetic materials and coatings for mag drive pumps can indeed help mitigate some of the disadvantages associated with their use. Let’s talk about some of these disadvantages.

Disadvantages & Limitations:

- Temperature & pressure resistance - Choosing high-quality magnetic materials with excellent temperature and pressure resistance can help overcome limitations in these areas. Advanced magnetic materials such as neodymium iron boron (NdFeB) or samarium cobalt (SmCo) offer superior performance in extreme environments, allowing mag drive pumps to operate effectively across a wider range of temperatures and pressures.

- Cost-Effectiveness - While mag drive pumps may have a higher upfront cost, selecting the right magnetic component can help optimize cost-effectiveness over the long term. By investing in high-quality magnets with exceptional durability and reliability, you can minimize maintenance requirements and downtime, resulting in lower total cost of ownership and greater return on investment.

- Efficiency Improvement - Innovative magnetic designs and materials can contribute to efficiency improvements in magnetic drive pumps. By optimizing magnetic pump coupling design configurations and minimizing energy losses, you can enhance pump efficiency and performance, narrowing the efficiency gap compared to traditional pumps.

- Sensitivity to External Factors - Careful selection of magnetic materials and shielding techniques can help reduce sensitivity to external factors such as magnetic interference or electrical surges. By employing advanced magnetic shielding materials and designs, you can enhance pump robustness and reliability, ensuring consistent performance even in challenging operating environments.

Precision Control and Process Optimization:

Precision control overflow rates, pressures, and dosing is critical in pump and fluid handling operations. Magnetic actuators and controls provide unparalleled precision and responsiveness, enabling operators to optimize process efficiency and product quality.

Our magnetic actuators are meticulously designed, rigorously tested, and calibrated to ensure optimal functionality and precision control. Whether you're dosing chemicals, additives, or other fluids, our actuators provide consistent and reliable fluid injection rates, optimizing process performance and ensuring product consistency batch after batch.

Furthermore, our magnetic bearings contribute to smooth, vibration-free operation in equipment, enhancing equipment longevity, and minimizing energy consumption. This is done by eliminating physical contact between rotating and stationary parts. This absence of friction reduces wear and tear, extending equipment longevity. Additionally, the lack of mechanical friction leads to minimal energy loss, thereby optimizing energy consumption and efficiency.

Corrosion Resistance and Environmental Compliance:

Chemicals, abrasive fluids, and harsh operating conditions present significant challenges for pump components and fluid handling equipment. At SM Magnetics, we offer a comprehensive range of corrosion-resistant magnetic materials and coatings designed to excel in the most challenging fluid handling environments. From advanced neodymium iron boron (NdFeB) materials to magnet coatings for harsh environments like gold, epoxy, and parylene.

Selecting the right magnet material and coating is crucial for ensuring equipment longevity and performance. With the diverse array of options available, it's essential to hire an expert in magnet material selection. Our team of specialists possesses deep expertise and industry knowledge, enabling us to recommend the optimal materials and coatings tailored to your specific application requirements.

We take safety standards and regulatory compliance very seriously and uphold our commitment to quality, safety, and ethical business practices while mitigating risks and ensuring long-term success. In pump and fluid handling, hermetically sealed magnetic designs provide a robust solution to mitigate the risk of fluid leakage and contamination in critical applications. By encapsulating the magnetic components within a sealed enclosure, these designs create a barrier that prevents fluids from entering or escaping the system. This not only ensures the integrity of the fluid handling process, but also safeguards against potential hazards and environmental contamination. In turn, adherence to safety standards and regulatory compliance is strengthened, promoting operational reliability and peace of mind for industries where fluid purity and safety are paramount.

Innovation in Magnet Technology:

Magnet technology continues to evolve, driven by innovation and advancements in materials science, engineering, and manufacturing processes. By staying at the forefront of magnet technology, companies can unlock new opportunities for improving reliability, efficiency, and safety. Our team of engineers, located in the US and overseas, are committed to developing new and improved materials to meet the demands of todays advanced technologies. Manufacturing advancements are equally as important at all our company-owned factories. Even small improvements can yield big results for our customers.

Conclusion:

In the demanding environments of pump and fluid handling applications, leveraging magnet expertise can make a significant difference in equipment reliability, process efficiency, and safety. By embracing innovative magnetic solutions, companies can minimize downtime, optimize performance, and ensure compliance with stringent regulatory requirements. At SM Magnetics we're committed to empowering our customers with cutting-edge magnet technologies that address their most pressing challenges and drive success in their operations. Contact us today to learn more about how we can support your business objectives with our magnet expertise.

About SM Magnetics: SM Magnetics is privately owned company, providing assistance with permanent magnets, magnetic design & optimization, magnetic engineering services, and production. SuperMagnetMan is the online retail division of SM Magnetics, offering high quality time-saving solutions with a wide range of neodymium magnets and magnetic assemblies in stock.