Intro to Vibratory & Haptic Motor Assemblies: How They Work & Common Uses

By: Brad Proffitt, SM Magnetics Account Manager

Vibration and haptic motors are the common means used to provide feedback from a signal or touch. The feedback is vibration. Vibration is an effective indicator that an action has responded from a software or hardware. These vibratory and haptics motors are in many items we utilize every day such as consumer electronics, home appliances, automotive, and many health products.

Primary application areas of vibration motor may mainly penetrate the alerting to users, as the haptic technology develops day by day, enhancing the user experience and safety is becoming the mainstream strategy. Haptic motors involved in haptic technology bring humans back to the real world and diversify the interaction experiences. Generally, the integration of haptic vibration and touch screens makes the touch screen more intuitive and interactive, making the user feel immersive and more realistic. This intuitive and interactive experience can be easily found in games, smartphones, tablets, TVs, and digital signage turn up.

The integration of touch technology with consumer electronic devices has simplified the human beings' day-to-day activity. The rising demand for mobility, wireless technology, cloud computing, and human-machine interface has laddered consumer electronics' transition to next-generation home automation devices. Gamers are attracted by challenging scenarios, amazing graphics, exciting online play, and useful game design, including haptic motor into the game controller, which significantly enhances the gaming experience and increases the player's entertainment level.

Haptic technology is widely used in the automotive field, including touchscreen of the automotive dashboard, steering wheel, gas pedal, and car seat, people can receive haptic feedback from them via motor vibration, which also gives warnings to the driver since these always are in contact with the driver. More haptic feedback has been introduced to the dashboard touchscreen to provide the operator with tactile information about button-presses. The steering wheel can make the most of its tactile feedback to remind the driver of the fuel level and other driving hazards. It vibrates to notify the driver when it detects a lane without indication. The gas pedal also provides haptic signals for the driver—these signals design to warn about the distance to the car ahead and the optimum time to change gears. Haptic devices conveniently deliver the information and exhibit multi-touch functionality, high performance, and faster response, thus making the driving easier, safer, and comfortable.

Click here to View/Buy Haptic Motors

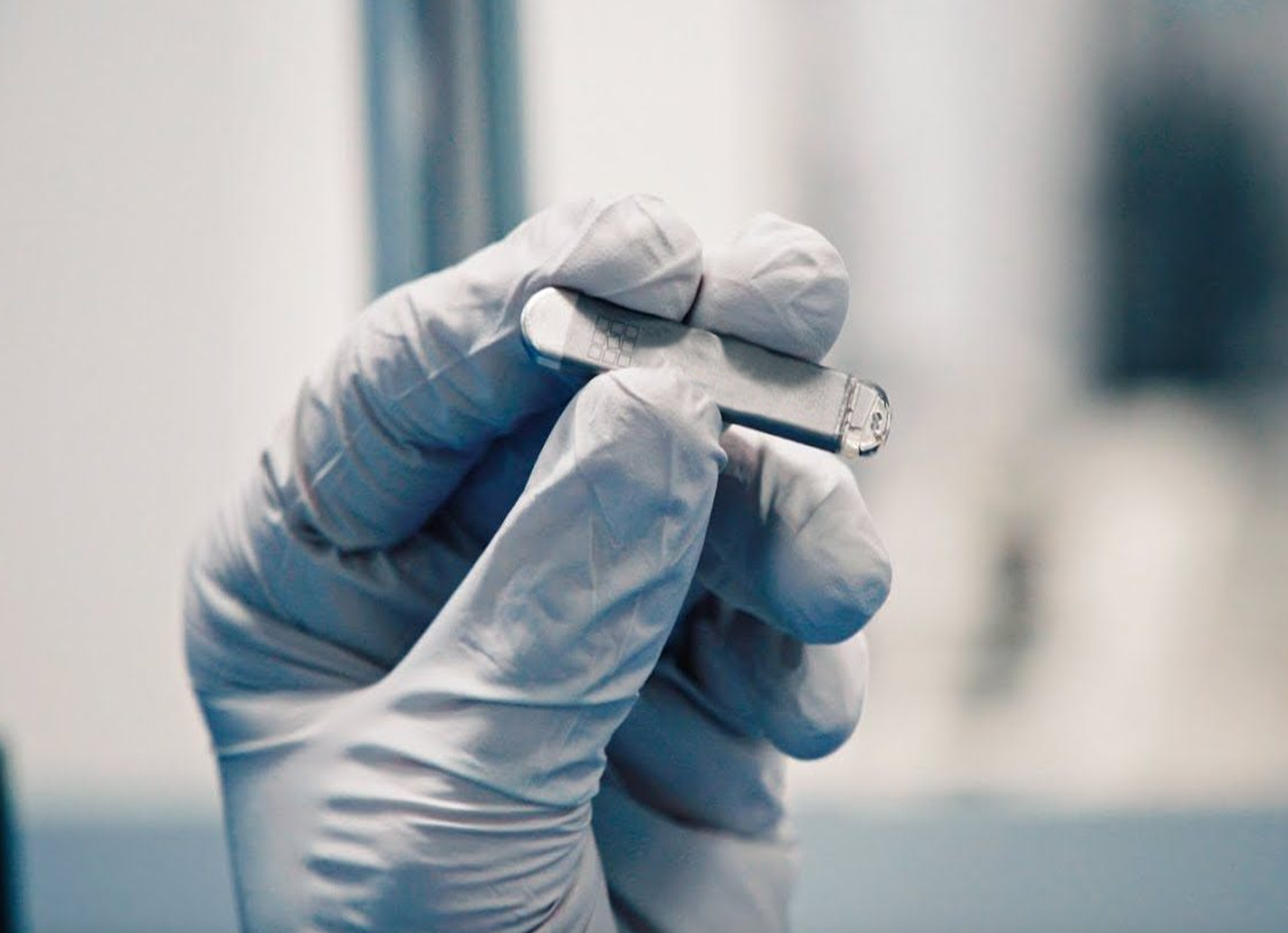

Our vibration motors are used in a variety of medical devices, including handheld health and beauty products, which both have becoming the trendy applications of haptic motors. Women are keen to maintain their beauty through various skin care products, skin massage, and even cosmetic surgery. Nowadays, different skincare products are getting more popular and more strongly sought after by people. The new generation of skincare products, such as cleansers, facial devices, anti-wrinkle, and make-up devices, are all driven by tactile technology with tactile motors. Medical applications using vibration motors have a wide range of practical uses, from taking patient's temperature to diabetes screening. Applying vibrations to areas of pain or muscle tension can alleviate stress and discomfort for long-term chronic pain sufferers.

The basic vibratory motors are divided into 2 types and these are the ERM and LRA:

- ERM or Eccentric Rotation Mass (Coreless)

- LRA or Linear Resonant Actuator (Coin)

Both ERM and LRA are driven by the interaction between electrical magnetic field and magnetic field. Converting electrical energy into mechanical energy in the form of rotation or vibration. ERM vibration motors create an off-center rotation via loading a counterweight (eccentric weight) on a shaft or a configuration plane. LRA vibration motors vibrate on a single axis against a spring, composed of Z-axis LRA (vertical direction LRA) and X/Y-axis (horizonal direction LRA).

ERM and LRA vibration motors can vary from the way of vibration and form factor as described above. ERM motors are divided into cylindrical configurations with shaft loading mass and coin shape configurations. Other ERM motors include iron core rotatory motor, automotive motor and sonic motor. LRA motors are varied by the linear vibration direction, X/Y-axis or Z-axis.

Permanent magnets are a basic part in a typical haptic motor, which is used to interact with electrical field to generate magnetic induction, this is why the electrical energy can be converted into mechanical energy. For a typical ERM motor, laminations stackings are the fundamental component to stabilize and enhance the electrical magnetic field. For a typical LRA motor, there are no laminations, but vibration spring with specific frequency and moving mass (magnet + other mass) driven AC voltage is very critical. For both ERM and LRA, coils are the sole source of electrical magnetic field.

Vibratory motors are customizable based on the customers’ application and constraints, such as the way of vibration, the acceleration strength, response time, size, work voltage and current.

About SM Magnetics: SM Magnetics is privately owned company, providing assistance with permanent magnets, magnetic design & optimization, engineering support, and production. SuperMagnetMan is the online retail division of SM Magnetics now offering standard size vibratory motors in stock - Coreless, ERM Coin and DC Brushed. To browse our collection - click here. For a custom size please contact us to start the conversation.