Motor Design Considerations

Motor Design - Pre-Design Considerations

By: Brad Proffitt, SM Magnetics Account Manager

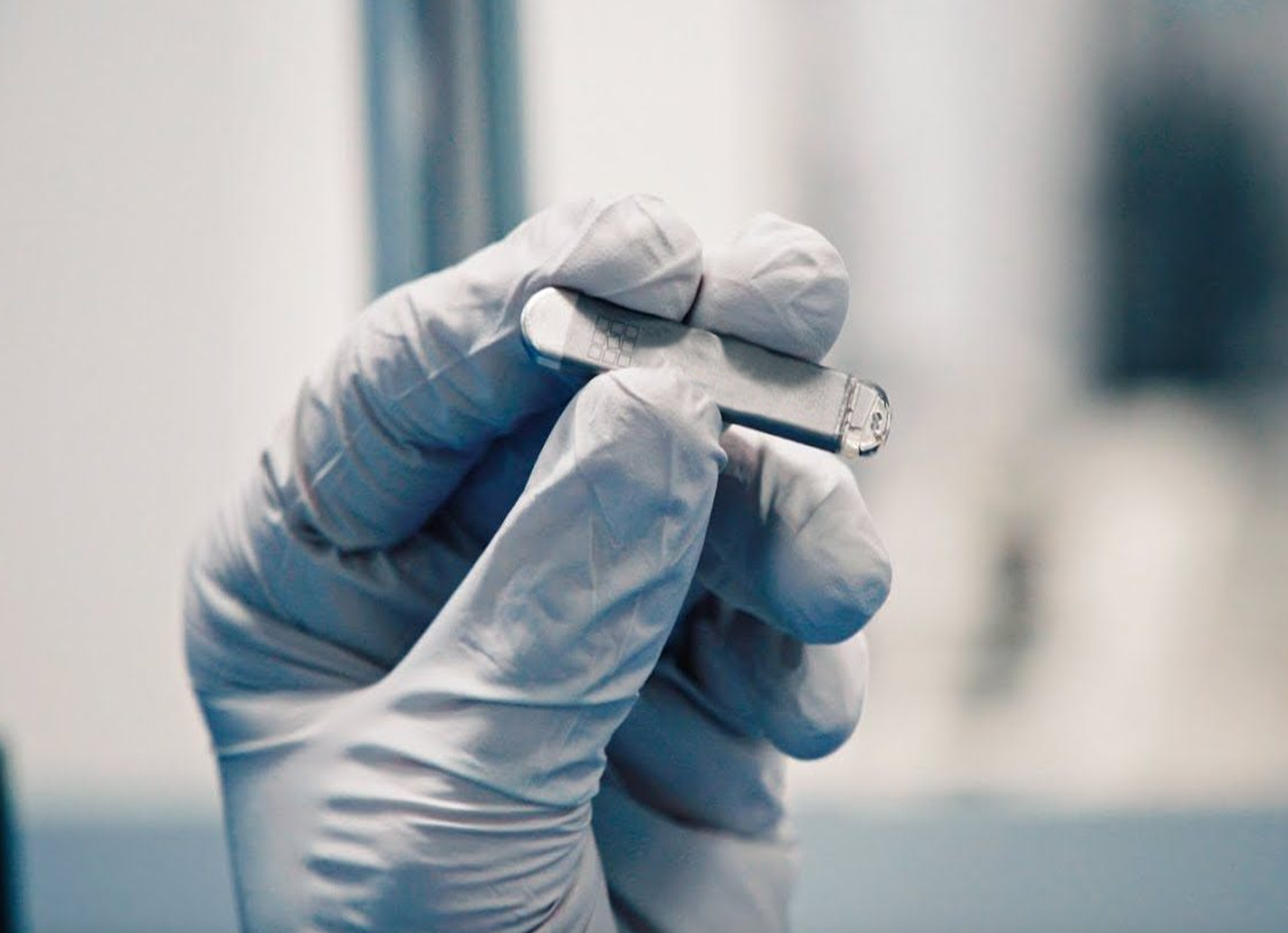

SM Magnetics has provided our customers with much advice on motor design; optimizing performance; and re-designing all, or parts of a motor. Once the design is ready for prototype, we manufacture their prototypes to determine any manufacturing issues involved before we go to production. To learn more about design assistance we have provided in the past for our motor customers click the link.

Motor design has many variables and details to consider, but we have defined 5 questions that allow us to have a starting point with our customers. These five questions are presented to help define the goals.

Click Here to View / Buy Neodymium Motor Magnets

Q: Where Should I Begin When Designing?

Our Thoughts: Begin at the most important place….the end. Beginning at “the end” is critical to a solid design and project flow since it defines the goals, budget, specifications, and operating environment of the motor.

Q: What function will the motor perform?

Our Thoughts: Be realistic. Define the function as accurately and with as much detail as possible. All plans start with a defined outcome, so make sure your end goal is specific, understandable, and achievable. A quick note about defining your end goal, remember to plan for changes, but not a complete overhaul unless completely warranted. Like all projects, set review points to determine if the motor project is still on the right track.

Q: What are the torque, horsepower, voltage, size limitation and other requirements?

Our Thoughts: Define these prior to starting any design since these factors will provide the guidance needed for magnets, wire size, lamination specifications and steel requirements. If the motor needs more torque then horsepower, design with that as your main factor while keeping your size limitations in mind. Answering the question “how much torque and horsepower do I need?” with the reply “as much as possible” will only result in countless revisions, too many prototypes, no defined end, and a blown budget.

Q: What is my Budget and My Defined Milestones? Should I Continue or Abort?

Our Thoughts: Know your limits. This may sound like simple advice, but motor development must involve limits on spending and milestones checks to determine if the motor is a project to pursue or abort. Setting up defined check points and asking tough questions at each checkpoint will make the decision much easier if you should pursue further development or abort the project. We understand this part of the process very well and have seen projects redirected, reconsidered, or completely aborted because advanced planning allowed for points during the development process to re-evaluation and review.

Q: What is the Operating Environment?

Our Thoughts: Understanding the operating environment of a motor is just as important as defining the motor specs. The magnets in the rotor must be carefully selected to operate in the environment. Will the motor operate at a temperature greater than 60C? Will it be exposed to salt or fresh water? Is it in an application where the stator wires (or laminations) should be completely covered? These are just some of the details that should be known before design so that the correct magnets, wire, laminations, steel, and coatings can be selected.

About SM Magnetics: SM Magnetics is privately owned company, providing assistance with permanent magnets, magnetic design & optimization, engineering support, and production. SuperMagnetMan is the online retail division of SM Magnetics offering neodymium magnets and other materials.