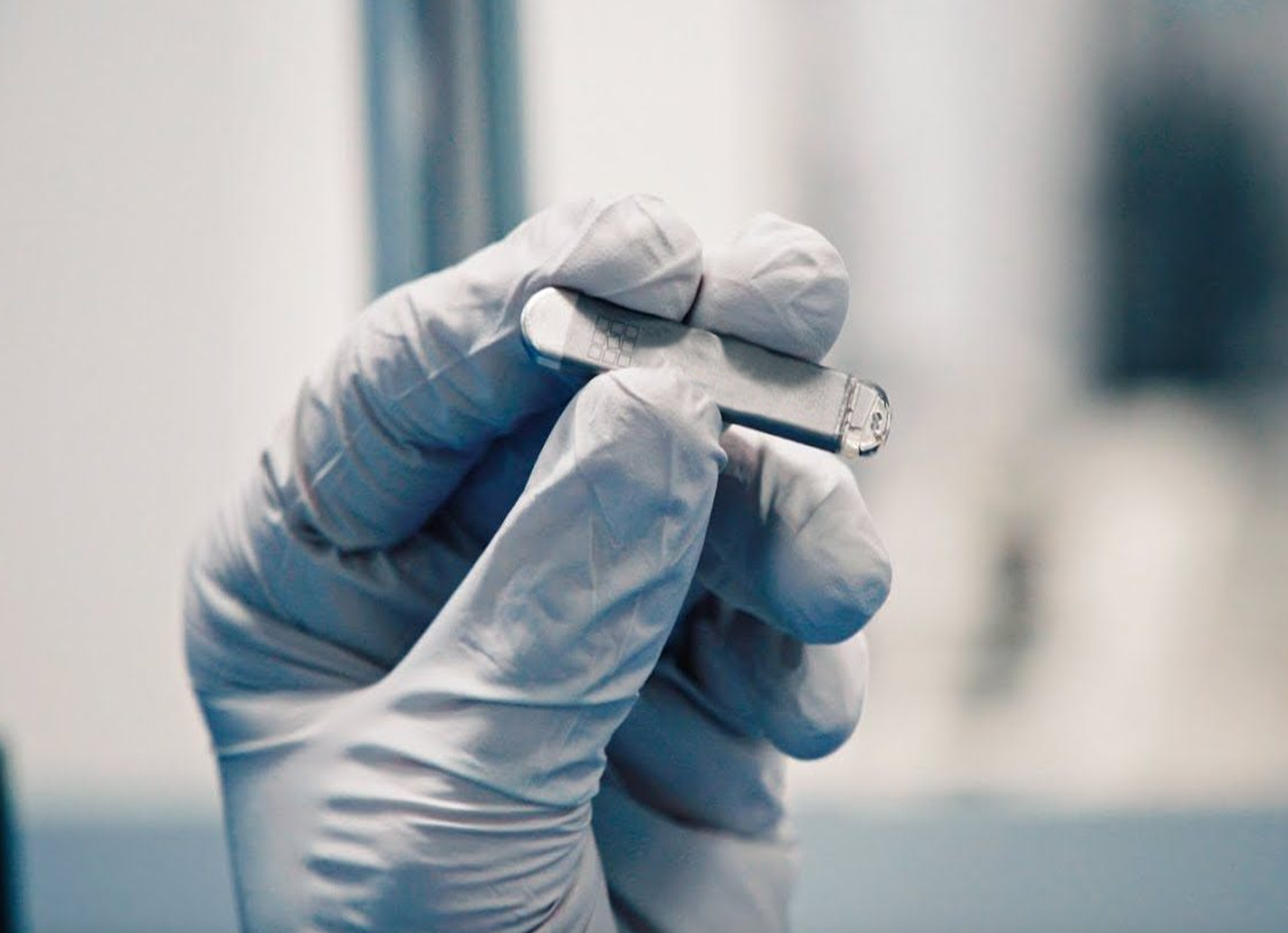

Motor Magnets - Arcs, Squares, Rectangles and Radial Rings

Motor design is a true balance of all materials: magnets, stators, laminations, wire size & insulations, etc. Choosing the best magnet begins with knowing your overall objectives with torque, RPM, and start-up load.

This article will only focus on the permanent magnet options for motors. The three (3) most commonly used permanent magnets used in motors are Neodymium Magnets, Samarium Cobalt (SmCo) Magnets, and Ferrite / Ceramic Magnets. Below is a summary of each magnet material, and an overview of their advantages and disadvantages.

Neodymium Magnets

Neodymium magnets are the strongest magnets on the market and give the most magnetic field in a motor circuit. They come in many material variations, and selection of the appropriate material will depend upon such items as temperature requirements, operating environment, and field strength. Below is a list of advantages and disadvantages for neodymium magnets:

Advantages

- High Induction (Br). Grades 30-55

- Good resistance to demagnetization (Hci)

- High Flux density / sq. cm (MGOe)

- Correctly selected material will last indefinitely

- Can reduce size / weight / size of rotor & stator

- Large selection of material grades

Disadvantages

- Can oxidize if not coated

- Lower working temp than some other materials

Summary

Neodymium Magnets will work well in an application that requires high stability, high induction over a lower operating temperature.

Click Here to buy Neodymium Magnets online at SuperMagnetMan

Samarium Cobalt Magnets

These magnets are the strongest magnets on the market after Neodymium Magnets. They come in several material variations, better known as SmCo 1-5, or SmCo 2-17. Below is a list of advantages and disadvantages:

Advantages

- High Induction (Br). Grades 16-32

- Great resistance to demagnetization (Hci), up to 350C

- Excellent resistance to oxidation without coating

Disadvantages

- High cost

- More brittle, easier to chip & break

Summary

Samarium Cobalt magnets will work well in a high temperature applications that requires a large resistance to demagnetization

Click Here to buy SmCo Magnets online at SuperMagnetMan

Ferrite / Ceramic Magnets

These magnets are the most widely used in motors due to lower cost. But with the low cost comes other trade offs. Below is a list of advantages and disadvantages:

Advantages

- Low cost

- Great resistance to oxidation

- Large abundance of raw materials

Disadvantages

- Low Induction (Br), Grades 1-10

- Usually requires a mold

- May deteriorate in magnetic field over time.

- Lower resistance to demagnetization

Summary

Ceramic magnets will work well in an application where greater concern is given over the size & weight requirements.

Click Here to buy Ferrite Magnets online at SuperMagnetMan

Picking the Correct Magnet

Each motor design is very different and working with an experienced magnet professional is important. The correct engineering partner can work through all of the design considerations, prototypes, changes, and manufacturability with you. Magnets can be made in many shapes and virtually any size, so getting the correct size. As a starting point to see what is available, check out the inventory of options at SuperMagnetMan with Arc Magnets, Square Magnets, Radial Rings, and Rectangle Magnets in stock. Don’t see the size, shape or material that you need, Request a Custom Magnet Quote.

About SM Magnetics: SM Magnetics is privately owned company, providing assistance with permanent magnets, magnetic design & optimization, engineering support, and production. SuperMagnetMan is the online retail division of SM Magnetics offering neodymium magnets and other materials.