Medical Magnets and the Associated Challenges

Magnets and Medical Applications

By: Andy Robinson, SM Magnetics Account Manager, Medical Industry

Permanent Magnets have long played a role in the medical industry. Examples of their applications include bodily use both internally and externally, motors for medical devices, and sensors. We continue to see a wide variety of uses for magnets in the medical industry and the innovation associated with today’s research and technology is as advanced as ever.

While each application is unique we see common themes that we work through with each of our customers. Developing a working partnership from the design and development phase, all the way through production, provides valuable insight and collaboration resulting in the best final product. Examples of the concepts we work through:

Product Application & Confidentiality

Most medical customers start with an idea or concept that they anticipate will be patented at some point, and warrants a mutual non-disclosure agreement (NDA) as discussions begin about the magnetics portion. Even without knowing the final application of the magnet we have successfully worked with medical customers on the design to prepare the part for production.

We respect and protect intellectual property (IP) of our customers, and understand that the incubation period for a new product can take a long time with many changes and continuous data collection along the way. While it can be challenging for us not to know the final application, we can still work through the requirements of the magnet or magnetic assembly to provide the correct simulations and optimized design before the first prototype is built. However, we also understand that the simulations and optimizations get close to a result for the final design, but there is no substitution for building prototypes and testing the actual design.

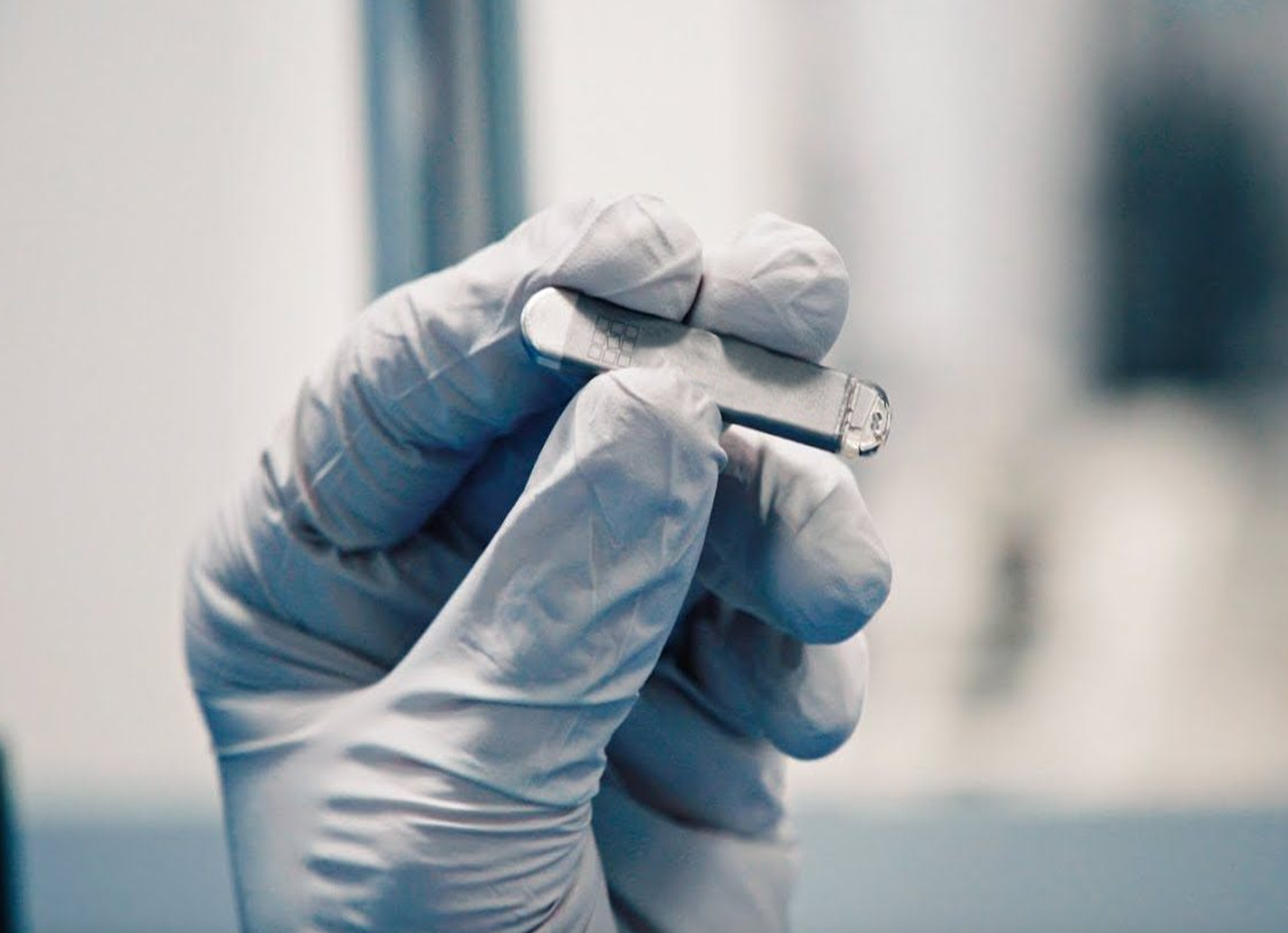

For Use in the Body?

Magnets used in the body take on requirements far beyond a “regular” magnet application. Here are some considerations we discuss with our medical customers for these applications.

Coatings: The FDA requires coatings that are biocompatible for medical magnets that are in contact with the body. For magnets, the approved coatings include gold, parylene, titanium, or rhodium. Correct coatings assist with corrosion resistance to certain chemicals and are also safe for internal use.

Click Here to View / Buy Parylene Coated Magnets

Click Here to View / Buy Gold Plated Magnets

Magnet Size: Almost all magnets for use in the body are small. Since a stronger magnet is required, neodymium is almost always used. Occasionally, we find an application that is trying to defy the laws of physics or asks a magnet to perform a task more than it is capable. For example, a tiny 0.5mm x 1mm cylinder magnet providing 20 lbs. of holding force, or a sensor reading 4000 gauss from a 1mm x 1mm disc from a 3” distance. For a magnet it is important to know the possibilities available in the size requirement, the acceptable tolerances (note: try not to be too tight if possible), and the outcome needed.

Magnet Shape and magnetic Orientation: Magnet shape is usually dependent upon the application and requirement of the outcome. Most magnets used inside the body tend to be small and cylindrical, while magnets used outside of the body take on many shapes and sizes. Just as important as the shape is the direction of magnetization or orientation. For example, one application we helped design had the magnet passing over a sensor. The initial design showed the magnet with an axial direction of magnetization, however, once we learned more about the sensor we realized that the direction of magnetization should be diametrical. Once corrected the sensor and magnet worked great as a team.

Temperature, Cleaning and Chemicals: Magnets will last indefinitely, well almost, if the correct magnet and coating are selected based upon the temperature, cleaning and chemicals to which it will be exposed. Neodymium magnets come in many grades so selecting the correct grade to handle the temperature requirement is a good starting point. Once the correct grade is determined, the environment to which the magnet will be exposed should be outlined. If a magnet will be cleaned with common chemicals or put in sterilization equipment, then a coating able to withstand this environment will be important. There are many options, so outlining any area where a magnet can encounter more than ambient air will be critical.

Documentation, Data Collection and FDA Requirements: Testing, testing, and more testing. Date collection, more data collection, and even more data collection. We understand the time and effort it takes to go from concept to an FDA approved product. We continually invest in, upgrade, and add to our technical and manufacturing capabilities so our customers have a complete resource from Prototype to Production. Each of our customers works with us to provide the list of documentation and reports required for each lot of products. Knowing what documentation and testing is needed during initial testing and production allows us, as the supplier, to get the correct testing procedures, manufacturing processes, and a checklist of documentation needed before we begin mass production. To learn more about our testing procedures read our blog article - Magnetic Measurements Techniques

The topics above are only a starting point when considering using magnets in medical applications. Advancements in medical technology and applications gives us the opportunity to work with some of the most innovative and creative minds in the medical industry today. They continue to challenge us to push the boundaries of magnets, magnet assemblies, magnet circuits, and coatings as it relates to applications for short-term surgical use, long-term placement of devices, and accurate use with sensors and precision motors.

About SM Magnetics: SM Magnetics is privately owned company, providing assistance with permanent magnets, magnetic design & optimization, engineering support, and production. SuperMagnetMan is the online retail division of SM Magnetics offering neodymium magnets and other materials.